A Closer Look at Controlling Corrosive Gases and VOCs

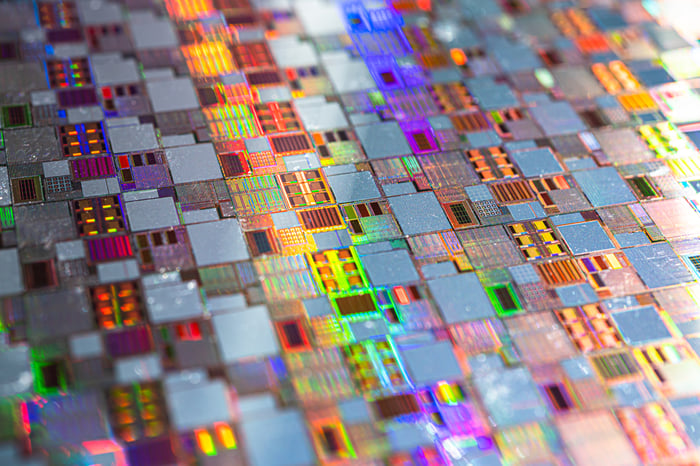

As the semiconductor industry propels us into an era of advanced smartphones and artificial intelligence, it simultaneously presents a unique set of safety and environmental challenges. The manufacturing processes inherent to this sector make extensive use of corrosive chemicals and volatile organic compounds (VOCs), necessitating robust control measures. In this critical arena, fiberglass-reinforced plastic (FRP) scrubbers emerge as the stalwart defenders against these hazardous pollutants.

The Role of FRP Scrubbers in Semiconductor Fabrication

Semiconductor fabrication is a complex dance of chemistry and physics, where purity is paramount, and even the slightest contamination can spell disaster for the delicate electronic components being produced. To manage this high-stakes environment, original equipment manufacturer (OEM) FRP scrubbers play a pivotal role.

Understanding OEM FRP Scrubbers

When we speak of OEM FRP scrubber systems within the industry, we refer to custom-designed solutions tailored to meet the specific needs of semiconductor manufacturing facilities. These systems are crafted from fiberglass-reinforced plastic—a material lauded for its resilience against a spectrum of chemical agents.

The Advantages of FRP Technology

Corrosion Resistance

With its nonreactive nature, FRP is an ideal candidate for enduring various chemicals without deterioration. This resilience ensures that operations can continue for extended periods without the frequent replacement cycles often associated with less robust materials.

Cost-Effectiveness

Comparatively speaking, FRP solutions present a more economical alternative to high-grade steel alloys typically required in similar corrosive environments. This affordability does not come at the expense of quality or reliability.

Capture Efficiency

Through advanced design, OEM FRP scrubbers achieve impressive capture efficiencies for both gaseous and particulate contaminants—ensuring that harmful substances are effectively removed from exhaust streams before they ever have a chance to reach the open atmosphere.

Low Maintenance Demands

Known for its low maintenance requisites, FRP does not rust or necessitate painting. Its smooth surface naturally repels contaminant buildup, simplifying cleaning routines and reducing overall upkeep costs.

Limitations Within the FRP Framework

Despite their many benefits, FRP scrubbers do have certain intrinsic limitations:

- Gas Temperature: Typically designed to handle inlet gas temperatures up to 220°F, these systems may require additional modifications, such as upstream evaporative quenches, to manage higher temperatures.

- Gas Pressure: Standard designs accommodate pressures up to 1 psig or 27.7 inches of water column. However, specialized designs can extend this range substantially when required.

- Erosion Risks: When faced with abrasive particles within gas streams, erosion can become a concern—potentially accelerating degradation if not properly addressed.

If you want a deeper dive into the function and applications of wet scrubbers, we’ve published a new white paper.

Controlling Harmful Emissions in Semiconductor Manufacturing

The semiconductor industry’s reliance on diverse corrosive chemicals and VOCs makes emission control a regulatory mandate and a corporate responsibility toward environmental sustainability. Here’s how OEM FRP scrubbers serve as an indispensable tool in this regard:

Neutralizing Hazardous Components

By absorbing and neutralizing hazardous chemicals through gas absorption techniques, FRP scrubbers protect workplace environments and external ecosystems from potential risks.

Customizable Solutions

Every semiconductor facility has its unique challenges based on the specific processes involved. Customizable materials used in creating OEM FRP scrubbers ensure that each system is precisely tuned to address these individual needs effectively.

Securing the Future of Semiconductor Innovation with Advanced FRP Emission Control

As semiconductor manufacturing continues its accelerated pace towards smaller components and larger data demands, the role played by OEM FRP scrubbers is becoming all the more critical. Through their ability to effectively contain and neutralize hazardous emissions, these systems represent an essential component in ensuring that our commitment to sustainability and safety matches our technological advancements.