Most every industrial application creates dust and other harmful particulate. To maintain safe levels of air quality and comply with regulatory agencies, particularly with combustible dust, you need a way to manage air quality control, like using a dust collector or wet scrubber.

According to the National Fire Protection Association (NFPA), combustible dust refers to any solid material composed of distinct particles or pieces less than 500 microns in size that can be a fire or deflagration hazard when suspended in air, or any other type of oxidizing medium, over a range of concentrations. Common examples of combustible dust include:

- Agricultural products, like egg whites, soy flour, and powdered milk

- Carbonaceous dust, such as coal, charcoal, and cellulose

- Metallic dusts, like iron, aluminum, titanium, and magnesium

- Plastic dusts, like polyacrylamide, polyethylene, and epoxy resins

The Dangers of Combustible Dust

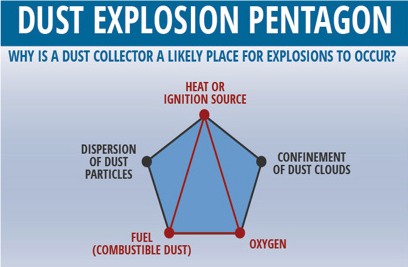

Combustible dust can be a big problem, leading to dangerous explosions within a baghouse if the dust isn’t managed properly. In fact, a dry dust collector can be an unfortunately ideal environment to trigger a dust explosion. All an explosion needs are five key conditions, each of which can occur within a baghouse:

- A combustible fuel, like dust

- Enough of a dispersion of dust particles

- Heat or an ignition source, like friction or static electricity

- Oxygen

- Confined dust clouds

Dust explosions can be catastrophic events, leading to the destruction of products and equipment – and worse – worker injuries and deaths. Hundreds of explosions have been documented by the Chemical Safety Board (CSB) over the years, with the Imperial Sugar Refinery explosion in Port Wentworth, Georgia, being an often-cited example, killing 14 employees and hospitalizing 40 others. According to the 2019 Mid-Year Combustible Dust Incident Report, there were 92 fires and 20 explosions between January and July alone.

Increased Regulations

In an effort to reduce the number of catastrophic events in the future, OSHA and the NFPA have continually implemented and updated regulatory standards to help companies mitigate the risk of a dust explosion. The NFPA’s most recent development is their NFPA 652, Standard on the Fundamentals of Combustible Dust.

Serving as a sort of “first-step” for the NFPA’s new combustible dust regulations, NFPA 652 builds upon other standards like NFPA 61, NFPA 484, and NFPA 654 in order to create a unique standard separate from industry- and commodity-specific regulations. The biggest impact that this will have on industry is the requirement for every applicable facility to perform a Dust Hazard Analysis (DHA) before the quickly approaching date of September 7, 2020. With the NFPA requiring DHA updates every five years, this will be the new regulatory standard for combustible dust control, even if you’re reading this past the deadline or have already completed your DHA for this year.

How to Prevent Baghouse Explosions

While the unequipped baghouse has multiple elements that make them more prone to explosions, there are multiple things that you can do to help prevent a spark, and the resulting explosion. Any of the following can be applied to a new dust collection system or an existing baghouse.

If you are using a baghouse or cartridge filter, you can equip your collector with explosion vents to help mitigate the risk of an explosion. Explosion venting offers a passive way to limit risk by exhausting flames and relieving pressures typically associated with a dust explosion. For more active preventative measures, consider using a chemical suppression system. You can also lower your risk for an explosion by implementing any of the following:

- Flameless venting or quench tubes

- Grounded/conductive filter bags

- External grounding of housing

- Electrical enclosures and wiring

All of these preventive measures add up to one thing – safer baghouses.

Can I Use a Wet Scrubber?

When it comes to reducing the risk of an industrial dust explosion and complying with NFPA standards, wet scrubbers – or wet dust collectors as they are sometimes called – can be a good option under the right conditions. By using scrubbing liquid to remove pollutants from an airstream instead of a filter media, the very mechanisms that allow wet scrubbers to work effectively mitigate the risk of a dust explosion. With a scrubbing solution, you can:

- Remove heat sources and friction

- Reduce dust clouds

- Prevent direct oxygen-to-dust contact

- Eliminate dust dispersion

Any of these on their own would help to reduce the risk of an explosion, but put them together and you can almost entirely eliminate the chance that an explosion will ever occur, at least within the wet scrubber itself. No matter whether you use a wet scrubber or a baghouse, you’ll still need to worry about any process upstream or downstream from the collector itself.

While effective for mitigating the risk of a dust explosion, wet scrubbers are not always the best choice for industrial air quality control, even when working with combustible dust. For instance, some dusts can be water-reactive, meaning that they can become hazardous when mixed with water. Scrubbers may also not adequately remove enough pollutants from an airstream in certain applications, particularly with processes that have heavy dust loadings, as the amount of water required may exceed desired efficiencies.

For more on recent NFPA regulations that specifically relate to wet scrubbers, take a look at their NFPA 484, Standard for Combustible Metals.

The Sly Difference

Sly’s guide, Using Wet Scrubbers for Combustible Dust Control, outlines the wide range of combustible dusts and explains how the use of a wet scrubber rather than a dry dust collection system can lower the risk of a dust explosion. It also provides an overview of the types of wet scrubbers available, as well as precautions and guidelines to follow if your facility must use a dry dust collection system instead of a wet scrubber.

At Sly, we work closely with our customers to evaluate their application in order to design the best solution for their specific needs. Even if you already have a dry dust collector installed or your application limits you to a dry dust collector, you can still reduce the chances for a dust explosion by following the advice in the guide. Download your copy of Using Wet Scrubbers for Combustible Dust Control to learn more about how to safeguard your facility and the people who work there. If you need help upgrading your approach to dust collection, contact us or request a quote.

Tags: explosive dust, wet scrubber