Wet scrubbers come in a variety of types and shapes, but all are basically designed to remove gases/vapors and particulates from the exhaust from process equipment like furnaces, dryers, mixers, bagging stations, etc. They’re often the best option for handling combustible particulates because they can eliminate the dust’s explosion potential. They are also well-suited for high temperature applications and those where moisture in the gas stream would quickly clog a dry dust collector.

Impinjet® Impingement Plate Scrubber

Impinjet® Wet Scrubbers collect particulates and clean, cool and absorb vapors and gases. They offer high collection efficiencies (99% for particles 5 microns or larger) with low water recirculation and minimum pressure drop. Impinjet scrubbers are highly resistant to fouling and available with capacities as high as 200,000+ CFM.

Impinjet® Wet Scrubbers collect particulates and clean, cool and absorb vapors and gases. They offer high collection efficiencies (99% for particles 5 microns or larger) with low water recirculation and minimum pressure drop. Impinjet scrubbers are highly resistant to fouling and available with capacities as high as 200,000+ CFM.

Impingement plate (or tray) scrubbers use a flowing bed of water across a perforated surface. The airflow is drawn into the scrubber and passes through the plate water. The water traps the contaminants, removing them from the airstream. Impingement plate systems typically use lower energy/lower pressure drop to scrub the gas.

Impingement scrubbers are suitable for particulate scrubbing and applications where both particulate and gaseous contaminants must be collected.

Venturi Scrubbers

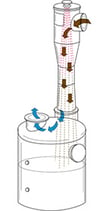

Venturi Scrubbers with cyclonic separators are often the best choice for high-efficiency collection of fine particulates. They use the differential between high-velocity gases and free-flowing water to create droplets that entrap contaminants and deliver them as a suspended solids solution.

Venturi Scrubbers with cyclonic separators are often the best choice for high-efficiency collection of fine particulates. They use the differential between high-velocity gases and free-flowing water to create droplets that entrap contaminants and deliver them as a suspended solids solution.

The venturi scrubber design requires more water and higher pressure drop to remove particulate than impingement plate scrubbers. The converging section of the venturi throat (where the water and airstream merge) creates atomized water droplets to provide efficiencies of 99 percent on particles 1 micron in size and larger. The efficiency can increase to 99.8 percent for particles 5 microns and larger.

Eductor Scrubbers

Eductor Venturi Scrubbers remove both soluble gases and particulates by inducing a gas flow using high-pressure liquid focused into a venturi throat. This eliminates the need for a separate exhaust fan or blower to transport the contaminant-laden airstream to the scrubber.

Eductor Venturi Scrubbers remove both soluble gases and particulates by inducing a gas flow using high-pressure liquid focused into a venturi throat. This eliminates the need for a separate exhaust fan or blower to transport the contaminant-laden airstream to the scrubber.

Eductor venturi scrubbers can also be used for direct-contact condensation. A high liquid flow rate makes this type of scrubber particularly well-suited for collecting sticky and/or gummy particulate, as well as gases that decompose on contact with water. Eductor scrubbers are often used in combination with other collection devices such as packed tower scrubbers.

Packed Tower Scrubbers

Packed Towers are designed for chemical scrubbing of gaseous contaminants and are often used to remove sulfur dioxide, hydrogen chloride, ammonia, hydrogen sulfide, and other gases.

Packed Towers are designed for chemical scrubbing of gaseous contaminants and are often used to remove sulfur dioxide, hydrogen chloride, ammonia, hydrogen sulfide, and other gases.

In vertical scrubbers, the gas flows upward through the bed, while the liquid trickles downward by gravity through the packing, which is typically made up of small plastic or metal objects. The liquid wets the surfaces of the packing materials, which are designed to provide a large amount of surface area for contact between gas and liquid. A liquid distribution header located above the packing evenly distributes the scrubbing solution across the top of the packing. Recirculated scrubbing liquid typically contains alkaline, acid, or oxidizing scrubbing agents to achieve the desired outlet emissions. Prior to leaving the scrubber, the scrubbed air passes through a mesh or chevron style mist eliminator to remove entrained droplets.

Want to learn more about how a wet scrubber can help you comply with the strictest environmental regulations without breaking your budget?

Download a free copy of Sly’s Wet Scrubber Buyer's Guide, which outlines basic criteria for selecting and specifying a wet scrubber.

Tags: wet scrubber, venturi