You’ve probably heard of a venturi, but do you know what it actually is or how it relates to dust collection? Let’s start with the basics. The Mirriam-Webster dictionary defines “venturi” as:

A short tube with a tapering constriction in the middle that causes an increase in the velocity of flow of a fluid and a corresponding decrease in fluid pressure and that is used especially in measuring fluid flow or for creating a suction (as for driving aircraft instruments or drawing fuel into the flow stream of a carburetor.)

Why Do You Need a Venturi?

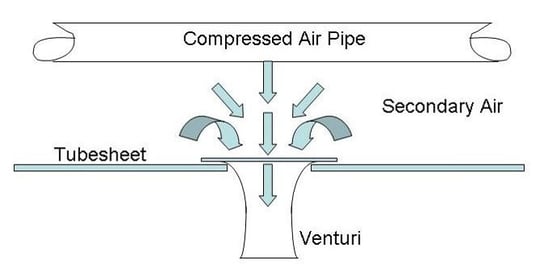

In short, in dry powder dust collectors the venturi creates a secondary airflow to amplify the pulse cleaning of the filter bags. A venturi is economical when you have longer filter bags or a large number of filter bags in a row and more cleaning air is required. Compressed air is typically the costliest utility in the operation of a dust collection system.

The venturi acts like an eductor to create the secondary air flow that is coupled to the compressed air pulse to enhance the amount of cleaning air for removal of a dust cake from the filter bags. Without the venturi, the volume of cleaning air may be insufficient for the amount of filter media that needs to be cleaned.

A typical baghouse operates at an air-to-cloth ratio between 3:1 and 6:1. This means that it filters between three to six cubic feet of air per minute through every square foot of filter media. The air-to-cloth ratio is selected based on the process conditions, including dust type, dust loading, and particle sizes, and its selection is typically driven by past experience.

For proper filter media cleaning, more air must be pushed backwards through the filter than is pulled in through the media. That is, we need to “back pulse” with four to seven CFM per square foot just to push the collected dust off the filter surface. This typically requires more air than just the compressed air pulse. The secondary airflow helps achieve this.

Converging-Diverging Venturi

In addition to creating the secondary air flow, a venturi helps air reach farther down the filter bag when longer bags are used. The venturi’s “converging-diverging” nozzle accomplishes this. The venturi consists of a converging section, the venturi throat and the diverging section. This design converts pulse pressure into flow at the throat and then creates pressure regain in the diverging section so the compressed air is not lost exiting the venturi. A proper venturi includes both the converging and diverging sections, and is not a simple funnel shape.

Flow leaving the holes in the air distribution pulse pipes above the venturis is limited by physics to sonic velocity. Passing the pulse of compressed air through a converging-diverging venturi achieves a supersonic, accelerated airflow to help project the pulse further down the filter bag.

Overall, there is some debate in the industry over the value of a venturi, and some manufacturers skip using a venturi. Sly’s experts believe in the value of a venturi and it is an integral part of all Sly baghouse dust collectors.

If you’re having trouble getting your filter bags clean enough, re-working your cleaning system to include venturis may be the right solution for you. Contact us or request a quote and we’ll design the right system for your application. We have more than 143 years of dust collection experience and expertise.

Tags: dust collection system, venturi