When most of us think about industrial dust collection, we think of dry dust filtration equipment. However, there are wet scrubbers that may be a better solution for controlling plant emissions and air pollution in many situations.

When most of us think about industrial dust collection, we think of dry dust filtration equipment. However, there are wet scrubbers that may be a better solution for controlling plant emissions and air pollution in many situations.

The Wet Scrubber Process

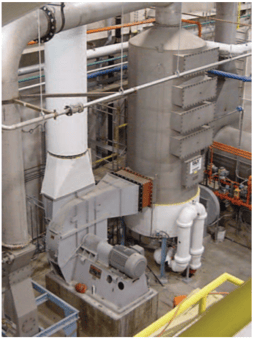

Wet scrubbers are systems designed to remove, clean or “scrub” contaminants from an air stream using a scrubbing fluid or solution. The contaminants can be dust, particulate, gases, oils, mists, and fumes from industrial exhaust air or gas streams. A scrubber works by intimately mixing a pollutant laden exhaust stream with a liquid such that the pollutants are captured by the liquid. The liquid can be water-based or organic-based.

Types of Wet Scrubbers

There are different scrubber designs that are based on the nature and properties of the pollutants to be captured:

- Impinjet® Impingement Plate: These clean, cool and absorb vapors and gases, and collect particulates. These are best used for applications requiring condensing and particulate removal.

- Venturi: These scrubbers are used to collect fine particulates and liquid mists, and are used for high temperature and/or highly corrosive applications.

- Eductor: These are designed to remove soluble gases and particulates by inducing a gas flow using high pressure liquid focused into the venturi throat. These can also be used for direct contact condensation, and to remove sticky or gummy particulates and gases which decompose upon contact with water.

- Packed Tower: These are designed for chemical scrubbing of gaseous contaminants from air streams. They can handle a wide range of airflows and can ventilate harmful, toxic gas streams and exhaust clean air back to the atmosphere.

When to Use a Wet Scrubber

As mentioned above, there are types of dust and pollutants for which a wet scrubber is better than a dry collector.

Combustible/Hazardous Dusts

Wet scrubbers are a safer choice for collecting combustible dust particulates. Using water as the collection media eliminates the dust cloud and explosion potential by wetting the dust and saturating the air stream. There is no threat of an ignition source, as long as the media being used is not a combustible gas. Combustibility can be a concern when handling dry metal fines, chemicals and many organic materials.

High Temperature Gases

Wet scrubbers can handle high-temperature applications without any special design considerations or replacement parts. Many processes require extremely high temperatures, including furnaces, kilns and incinerators.

Adding water into a wet scrubber system does not affect its operation, so a quench system can be employed prior to the inlet to the scrubber. The pre-quench section combined with the scrubber can handle temperatures higher than 2,000 degrees F. By comparison, conventional baghouse technology is available for temperatures up to only 550 degrees F. Dry baghouse technology at higher temperatures carries exponentially higher initial costs.

Moisture in the Gas Stream

Processes that have moisture content in their gas stream can cause havoc on dry dust collectors by causing caking on filter bags, plugging equipment and altering pressures. Wet scrubbers use water to saturate the gas stream to remove particulates, so the moist process gas doesn’t cause the problematic issues one would find with a dry dust collector.

As equipment like dryers and kilns drive off moisture from the product, the air or gas used in the process carries it into the dust collector. Wet scrubbers are not affected by this moist or wet air, and do not require compressed air, insulation or auxiliary heat that are often needed for dry dust collectors used for this application.

Particulate and Gaseous Contaminants

For applications that need to remove both particulate and gaseous contaminants from the airstream before being vented to the atmosphere, wet scrubbers may be able to collect both with one piece of equipment. Dry dust collectors only collect solid particulate. You would need additional equipment to remove the gases.

Wet Scrubber Benefits

Don’t overlook the cost saving potential with using wet scrubbers. They offer:

- Lower initial capital costs and maintenance costs

- Better energy savings

- Smaller footprint

- No replacement bags needed

Tags: wet scrubber